WPC use polyethylene, polypropylene mix with more than 35% to 70% of wood powder, rice husk, straw waste plant fiber blend into wooden material, then extrusion.

It mainly used in building materials, furniture, logistics packaging industries.

Wood plastic composites have both advantages of plastic and wood. The surface hardness is high, generally 2-5 times than wood.

The PE WPC profile extrusion line is suitable for producing the hollow/solid PE WPC profiles.

This profile has the advantage of fireproof, waterproof, moisture proof, moth proof, mildew proof and environment friendly.

It is mainly used for extruding outdoor decorative WPC profiles, such as gardening landscapes, outdoor landscapes, pallets etc.

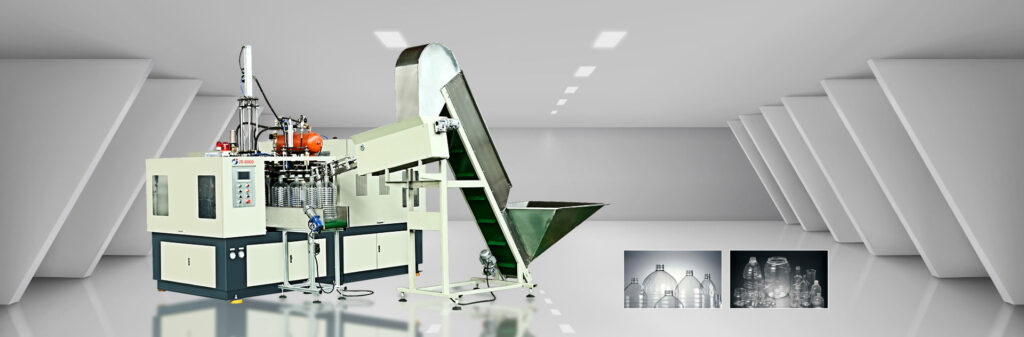

PP/PE WPC profile extrusion line

WPC Extrusion Machine

WPC Extrusion Machine is Wood Plastic Composite Production line, It use new or recycled PP PE PVC to produce Profile, Board etc products.

| Plastic | Formulation | Final Product |

| PVC | 10%-30% wood powder or natural fiber, 70%-90% PVC | Door Frame, Door Board, Furniture Board, Decoration Board, Wall Panel etc |

| PP/PE | 50%-70% Wood powder or natural fiber, 30%-50% PP/PE | Railing, Fencing, Decking, Flooring, Pillar, etc |

WPC PE Decking Profile Extrusion Machine

WPC PE Decking Profile Extrusion Machine can produce WPC outdoor decking from recycled PE and Wood Powder.

By Changing Mould, it can produce WPC Fencing, WPC Pillar, WPC Pole, WPC Pipe etc.

WPC Decking Manufacturing Process:

Extruder- Mould-Calibrating Table-Haul Off Machine-Cutting Machine-Stacker

(Customer can purchase WPC granule, or do WPC granulating according to budget)

What is Wood Plastic Composite Decking?

Wood Plastic Composite (WPC) Decking is a light-weight, inexpensive alternative to traditional wooden decking.

WPC Decking is made of a specially engineered combination of 50% recycled hardwood fiber, 40% recycled PE/PP and a 10% mix of bonding agents and color tints.

This means that our WPC decking is designed to be stronger than traditional wood options as the wood is reinforced by the bonding agent.

Unlike a completely natural wood, WPC boards stand the test of time as they are not weakened by weathering.

WPC Decking will withstand temperature fluctuations and moisture.

Surface Processing Machine for WPC Decking

- Embossing Machine (Online or Offline embossing available)

- Sanding Machine

- Brushing Machine

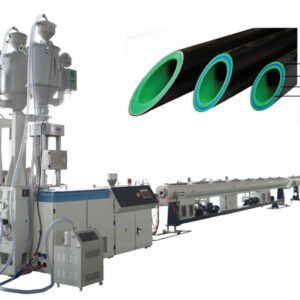

he PE WPC profile extrusion line is suitable for producing the hollow/solid PE WPC profiles.

This profile has the advantage of fireproof, waterproof, moisture proof, moth proof, mildew proof and environment friendly.

It is mainly used for extruding outdoor decorative WPC profiles, such as gardening landscapes, outdoor landscapes, pallets etc.

Technical data

| Item/model | SJMS-51/105 | SJMS-65/132 | SJMS-65/132 | SJMS-80/156 |

| Max. Product width | 200mm | 250mm | 250mm | 400mm |

| Extruder capacity | 100kg/h-120kg/h | 150kg/h-180kg/h | 150kg/h-180kg/h | 350kg/h-380kg/h |

| Main motor power | 22kW | 37kW | 37kW | 75kW |

| Vacuum pump power | 3kW | 5.5kW | 7.5kW*5.5kW | 11kW*7.5kW |

| Calibrating platform length | 4000mm | 6000mm | 8000mm | 6000mm |

Co-extrusion colorful PP/PE WPC decking extrusion line

This extrusion line is for producing co-extrusion PP/PE WPC decking. The decking surface can be made into wood grain by co-extruder.

Further, the machine can be equipped with on-line embossing device the surface can be made into 3D wood grain.

The WPC decking has a series of advantage including water-proof, insect prevention, ageing resistant, easy installation, environment friendly and good weathering resistance.

WPC Extrusion Machine

WPC Extrusion Machine is Wood Plastic Composite Production line, It use new or recycled PP PE PVC to produce Profile, Board etc products.

| Plastic | Formulation | Final Product |

| PVC | 10%-30% wood powder or natural fiber, 70%-90% PVC | Door Frame, Door Board, Furniture Board, Decoration Board, Wall Panel etc |

| PP/PE | 50%-70% Wood powder or natural fiber, 30%-50% PP/PE | Railing, Fencing, Decking, Flooring, Pillar, etc |

There are no reviews yet.